More about eye protection

TEST METHODS FOR EYE PROTECTION

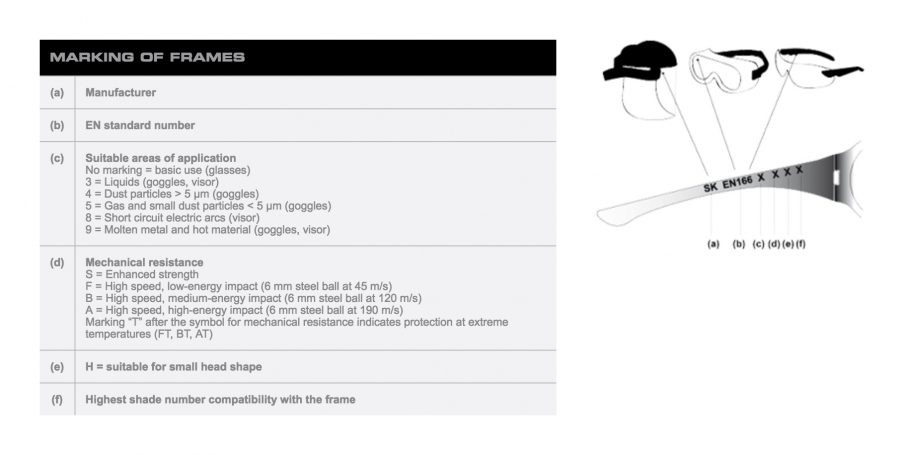

Mechanical test according to EN 166 (Enhanced strength) is performed, among others, through a 22 mm diameter steel ball being released on the glass at a speed of 5.1 m/s. “S” specifies that this test has been carried out.

ADDITIONAL TEST FOR PROTECTION TO WITHSTAND HIGH-VELOCITY PARTICLES

A 6 mm diameter steel ball is used and is fired at the protective glass.

Low energy impact 45 m/s is marked with “F”. (Glasses, Goggles, Visors)

Medium energy impact 120 m/s is marked with “B”. (Goggles, Visors)

High energy impact 190 m/s is marked with “A”. (Visor)

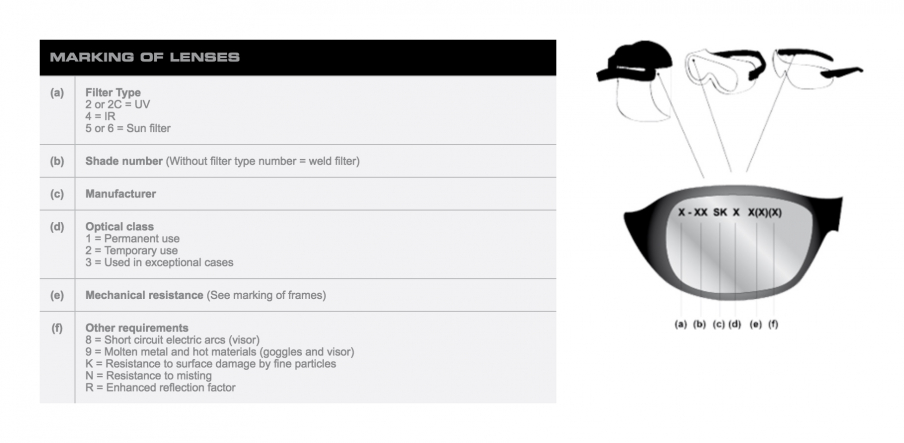

OPTICAL TEST

The optical quality of eye protection is divided into 3 classes. Lenses are marked 1, 2 and 3.

Class 1 is the best class with regard to optical properties.

Welding marking

EN standards

| Standard | Description |

|---|---|

|

EN 166 |

Eye protection, requirements and specifications |

|

EN 167 |

Eye protection, optical test methods |

|

EN 168 |

Mechanical tests Describes the different mechanical testing methods in accordance with the requirements in EN 166 and other standards for eye protection. |

| EN 169 |

Eye protection, welding filters |

| EN 170 |

Describes filter requirements for UV radiation |

| EN 171 |

Describes filter requirements for IR radiation |

| EN 172 |

Sunglasses for professional use, even with glare |

| EN 175 |

Eye and face protection during welding |

| EN 207/208 |

Filters against laser radiation/Filter for the adjustment of the laser. |

| EN 379 |

Eye protection, welding filter with automatically darkening welding glass (switchable luminous flux transmittance or double luminous flux transmittance). |

| EB 1731 |

Eye and face protection with wire mesh against mechanical hazards and/or heat for professional use or other uses. |

Sweden

Sweden Norway

Norway